A Comprehensive Supply Chain Risk Assessment Guide for Modern Procurement & Supply Chain Teams

World markets continue to evolve, and one of the natural forces is for these markets to grow. A corollary to this growth is that competition across the globe will grow as well. This means that the world marketplace is now and will be in the future a part of many companies’ supply base.

Supply chain risk isn’t a side conversation anymore. It isn’t a paragraph in a PowerPoint or a bullet hiding in a quarterly report. It has become one of the most defining operational priorities of modern business. When the supply chain breaks down, companies lose revenue, customers shift to competitors, production lines sit idle, and EBITDA evaporates faster than leadership can schedule emergency board meetings.

What separates resilient organizations from fragile ones is simple: visibility + preparedness.

A Supply Chain Risk Assessment and decisions on mitigation give you both.

What Is a Supply Chain Risk Assessment?

A Supply Chain Risk Assessment is a structured process used in Supplier Risk Management to identify, evaluate, rank, and mitigate threats that can impact the continuous flow of materials, information, and services throughout your supply chain. The process covers every node: raw materials for tier-one tier-two and tier three suppliers, logistics providers – ports – infrastructure, and even your internal processes including ERP / MRP systems.

Risks can come from dozens of Supplier Performance Risks:

- A supplier suddenly shutting down

- A region under political sanctions

- A raw material shortage

- Labor strikes

- Port congestion

- Hurricanes, typhoons, earthquakes

- A ransomware attack on a supplier’s ERP portal

- Carriers going bankrupt

- Global spikes in demand for your core materials

Any of these can halt production, starve your plant of required components, or create cascading delays that send delivery performance into freefall.

In an era of globalized sourcing, just-in-time inventory, and extended logistics timelines, proactive risk identification has become a mandatory core competency — not a “nice-to-have.”

High-performing procurement organizations no longer ask whether risk will occur.

They ask, ‘where can these failures happen – how fast can we respond when they do,’ and this is where actions derived from a Supply Chain Risk Assessment and Supply Chain Disruption Prevention Plan comes in.

Why Supply Chain Risk Assessment Matters More Than Ever

Before 2020, supply chain risk was on the radar — but it was usually buried under everyday urgency. The pandemic, port shutdowns, semiconductor shortages, geopolitical instability, and dramatic freight volatility changed the industry overnight and permanently.

Modern supply chains face:

- Longer lead times and unstable capacity

- Critical components that are single-sourced

- Raw material volatility

- Skyrocketing international freight costs

- Sudden regulatory or tariff barriers

- Lean inventory strategies with no cushion

- Labor shortages affecting manufacturing and logistics

- ESG compliance pressure that affects supplier approval

The reality is harsh:

A company without a Supply Chain Risk Assessment and a mitigation strategy is a company one crisis away from a shutdown.

Supply chain vulnerability is no longer theoretical — it’s a measurable financial threat. CFOs track it, boards discuss it and your customers feel it when operations falter.

Supplier Risk Management is not a ‘one-off’ project, it is an ‘everyday’ opportunity.

It is infrastructure.

Common Types of Supply Chain Risks that a Supply Chain Risk Assessment Can Reveal

Each risk category impacts your business differently — but all of them threaten supply continuity, customer delivery, and profitability.

Supplier Chain Vulnerability

- Single-source suppliers

- Critical Raw Material Shortages

- Adverse and/or Unpredictable Weather

- Political instability

- Global / Intercontinental Supply Chains

- Financial instability

- Chronic quality issues

- Late or inconsistent deliveries

- Lack of business continuity planning

These weaknesses create immediate operational exposure.

Material & Component Shortages

High demand or constrained capacity quickly push out lead times. Specialized materials — certain resins, metals, chemicals, PCB substrates, semiconductors — can become constrained without warning.

Logistics & Transportation Failures

Disruptions include:

- Port congestion

- Extreme weather

- Fuel price spikes

- Carrier bankruptcy

- Driver shortages

Any logistics disruption can ripple into production schedules.

Geographic & Political Risk

Regional issues carry outsized impacts:

- Tariffs

- Sanctions

- Border closures

- Political instability

- Wars or strategic conflicts

Geopolitical risk is one reason regional diversification has become a top procurement strategy.

Operational & Process Risk

Inside your own walls: Internal weaknesses compound external disruptions.

- Inaccurate forecasting

- No safety stock strategy

- Erroneous BOM accuracy that leads to inaccurate inventory levels

- Lack of standardized purchasing processes

- Poor cross-functional communication

These matters should be resolved by ensuring that the company has the right processes in place, e.g., Bill of Material accuracy. A simple cycle counting program reveals when the usage of raw material is inaccurate.

Cybersecurity & Data Risk

Your supplier ecosystem is only as secure as the least secure company connected to your ERP or portal.

Threats include:

- Ransomware

- Data breaches

- Compromised VPN/portal access

- Hacked logistics tracking

The cost of a cyber lapse can easily exceed the cost of a material shortage.

How to Conduct a Supply Chain Risk Assessment (Step-by-Step)

A comprehensive Supply Chain Risk Assessment involves multiple layers of visibility, ranking, and mitigation. Here’s the framework used by world-class procurement teams:

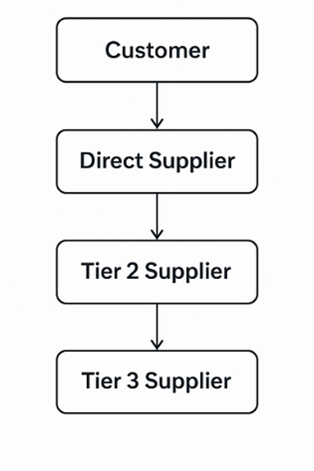

1. Map the Supply Chain (End-to-End)

Document the full supply chain flow from raw materials to customer delivery.

This includes:

- Tier-1 suppliers

- Tier-2 and Tier-3 upstream sources

- Contract manufacturers

- Logistics partners

- Ports and regions

- Manufacturing plants

- Warehouses and distribution centers

Getting information about your suppliers’ supply chain is anything but easy since inquiries about these tertiary suppliers can be difficult to get. Most companies must claim and protect this as confidential and company proprietary (as they too may have or should have agreed to confidentiality about a partner’s information). However, by using bilateral non-disclosure agreements, you should be able to get enough information and/or assurance from your supplier that the company has done its own due diligence on risk assessment and business continuity planning of those tertiary suppliers.

The goal: understand every node where failure could occur.

2. Identify Single Points of Failure

This is the “pulse check.”

Anywhere your supply chain depends on one supplier, one factory, one region, or one critical material, you carry amplified risk.

Examples:

- Single PCB supplier

- Single molding facility

- Single resin grade unique to one producer

- Single tool located at a supplier’s plant

3. Evaluate Supplier Stability

Operational & Process Risk

Use objective scoring. The cleaner the scoring model, the better the visibility.

Key metrics include:

- Quality rating

- On-time delivery performance

- Financial stability

- Capacity availability

- ESG compliance

- Lead time consistency

- Results from a Supplier Self-Assessment Survey

- Operational Maturity from a Supplier Operations Audit, Add link here to GYPD Supplier Operations Audit

Tools such as supplier scorecards, audit reports, and risk surveys bring structure to supplier evaluation.

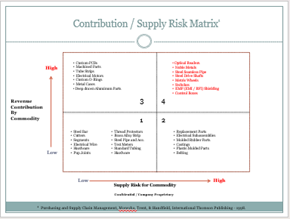

4. Assign Risk Probability + Impact Levels

This is where a risk scoring matrix can help. Two questions drive the scoring:

- How likely is the disruption?

- What is the financial/operational impact if it happens?

Probability and impact are ranked from Low / Medium / High, then combined into a risk rating that guides priorities.

Profit Contribution / Supply Chain Risk Assessment Matrix 1

1 Purchasing and Supply Chain Management, Monczka, Trent, Hndfield, International Thomson Publishing, 1998

You can find an example of a Supply Chain Risk Matrix by following the link below>

5. Build Mitigation Plans for the Highest Risks First

Risk mitigation should be practical and financially aligned with the impact.

Examples include:

- Dual, even multi-sourcing of critical components

- Adding safety stock for long-lead time materials and/or transit times

- Onboarding suppliers in separate regions

- Negotiating long-term price & capacity agreements

- Pre-approving alternate carriers

- Adding secondary tooling if necessary

6. Supply Base Optimization

Supplier Optimization sits at the intersection of strategy, discipline, and sheer operational horsepower. At its core, the objective is simple enough: concentrate your spending with the suppliers who consistently perform at world-class levels. The execution, however, is anything but simple. Managing a supply base requires real resources, and spreading those resources thin across too many suppliers dilutes performance and invites risk. When companies intentionally narrow their supplier roster within each commodity, they create the runway to focus deeply on the partners who move the needle—driving improvements in quality, on-time delivery, cost competitiveness, and overall reliability.

This approach also mirrors the logic behind corporate mergers: eliminating redundancy reduces operational costs and strengthens buying power, provided the consolidation doesn’t compromise supply continuity. Fewer suppliers make it easier to implement advanced procurement systems, maintain consistent processes, and enforce performance expectations without drowning the organization in administrative burden.

Even the idea of reducing risk by reducing suppliers can sound counterintuitive, but it’s rooted in simple math and attention. When you’re able to dedicate more time and support to fewer suppliers, you drive down the very risks—quality failures, late shipments, cost instability—that cause disruption in the first place. Of course, this only works when decisions are grounded in a rigorous Risk Assessment and a thoughtful mitigation plan.

And when it comes to New Product Introduction, the logic becomes even clearer. Launching new products is hard enough with well-defined procedures, and “early supplier involvement” only helps if the right suppliers are involved. Coordinating one or two strategic partners through R&D, prototyping, testing, and production is drastically more efficient than juggling a crowd of less aligned suppliers.

These themes only scratch the surface. Supplier Optimization is a massive discipline—part financial strategy, part operational engineering, part procurement risk management—and it deserves its own deep dive. I’ll cover the full roadmap, metrics, and playbook in a dedicated upcoming article on building a truly World-Class Supply Base.

7. Continuously Monitor Risk

Risk management never ends. Best-in-class companies work to create Supply Chain Resilience through risk assessment and Supply Chain Disruption Prevention that includes:

- Business Continuity Planning

- Quarterly Business Reviews (QBRs)

- Supplier risk dashboards

- ERP-or other ‘system driven alerts’

- KPI scorecards

- Regional intelligence monitoring

- Regular supplier capacity reviews

A risk identified is not a risk eliminated — it’s a risk that must be watched.

Proven Supply Chain Risk Mitigation Strategies

Dual SourcingEliminates reliance on a single supplierTwo or more suppliers for critical resins

| Strategy | Purpose | Example |

|---|---|---|

| Regional Diversification | Reduces exposure to geopolitical issues | China + Mexico + U.S. split |

| Inventory Segmentation | Protects most critical items | ABC analysis + safety stock |

| Supplier Scorecards | Improves visibility & accountability | Scored metrics for OTD, cost, quality |

| Contracts with Penalties | Enforces reliability | Fixed lead time with penalties |

| Contingency Logistics | Maintains shipment continuity | Pre-approved alternate carriers |

| Contingency Logistics | Maintains shipment continuity | Pre-approved alternate carriers |

These strategies help to shift the organization from “reactive firefighting” to controlled resilience.

Benefits of Performing Supply Chain Risk Assessment

Following a structured Supply Chain Risk Assessment program delivers massive benefits across finance, operations, procurement, and customer management. Advantages include,

- Preventing production downtime

- Protecting EBITDA and margins

- Strengthening customer delivery performance

- Reduceing emergency freight and expediting costs

- Improveing supplier accountability

- Enabling faster crisis response

- Supporting long-term business continuity

- Building a measurable supply chain resilience model

Companies that maintain visibility outperform competitors who only realize there’s a problem when the line shuts down.

Real-World Example: The Unimicron Plant Fire (2020–2021)

In October 2020, a significant fire had an impact on a Unimicron Technology plant in Taiwan, one of the world’s most important suppliers of printed circuit boards (PCBs) and IC substrates. A second fire followed in February 2021.

The global impact was immediate:

- Severe component shortages

- Extended lead times

- Material allocations

- Production halted at multiple OEMs

- Millions in expediting and lost revenue

For companies that were single-sourced, this was a full operational crisis.

For companies with dual-sourced PCBs, the disruption was painful but manageable. With alternative suppliers already qualified, they could:

- Keep production running

- Avoid missed shipments

- Prevent expedited-shipping costs

- Protect profitability

This is the difference between having a risk plan — and hoping a fire never happens.

Tools & Templates for Risk Management

If your organization doesn’t already have a formalized risk program, you can build one quickly using ready-made tools such as:

✓ Supply Chain Risk Scoring Matrix, Add link here to GYPD Profit Contribution and Supply Chain Risk Matrix

✓ Supplier Self-Assessment Survey

✓ Supply Chain Risk Assessment Playbook, Add link here to Supply Chain Risk Assessment Playbook

✓ Approval Limits in Purchasing Table, add link here to Approval Limits in Purchasing Table

All are available at GetYourPurchasingDocuments.com, ready to drop into your team’s process without months of development.

Final Takeaway

A Supply Chain Risk Assessment is no longer optional. It is the backbone of operational continuity, customer reliability, and financial stability. The companies that survive disruptions are not the biggest – they are the ones that invest in visibility, build redundancies where it matters, and act before a crisis forces their hand.

Risk doesn’t disappear. But with the right structure, it becomes predictable — and manageable.

You can learn more about Supply Chain Risk and other topics by following this link to the Association for Supply Chain Management website: