Quality and cost have been unfairly portrayed as mortal enemies for decades. One side pulls, the other side snaps, and leadership throws up their hands as if “good, fast, cheap—pick two” is a universal law of physics. But manufacturers who understand disciplined procurement know a better truth: You can cut manufacturing costs and maintain or improve quality by following a number of steps.

At GetYourPurchasingDocuments.com and Manufacturing and Supply Chain Services, this is the daily reality we help customers achieve.

You can absolutely cut manufacturing costs by 10–15% without touching your product design, lowering specifications, or upsetting customers—if you bring structure, control, measurement, and strategic supplier management into the equation.

Most organizations don’t have a cost problem—they have a process problem masquerading as a cost problem. Standardizing documentation, tightening supplier governance, and sharpening sourcing decisions allows you to cut manufacturing costs – savings that stick. No shortcuts. No reduced quality. No drama.

This long-form guide is your blueprint for capturing those savings in a sustainable, scalable way.

The Mindset Shift: Why Manufacturers Can’t Cut Manufacturing Costs Hiding in Plain Sight

Cost reduction is often misunderstood as a blunt-force activity – suppliers squeeze pricing, slash headcount. That’s not strategy; that’s panic dressed up as leadership.

The truth is far simpler and far more effective:

Waste hides in unstructured purchasing. Inefficiency hides in unclear expectations. Cost leaks thrive when internal control is missing, purchases aren’t managed, and suppliers aren’t measured.

Manufacturers who install a disciplined, documented procurement system routinely unlock:

- Lower material, freight, and overhead costs

- Achieve significant working-capital improvement

- Higher supplier accountability and fewer defects

- A supply chain that doesn’t fall apart when someone sneezes in a port halfway across the world

And they do it without ever touching product design or engineering specifications.

Four pillars drive these savings:

- Process discipline

- Supplier optimization

- Total Cost of Ownership (TCO) visibility

- Contract and performance governance

Let’s break each one open and show how the savings stack up.

Step 1: Replace Chaos with Process (That Can Cut Manufacturing Costs 3–5%)

Unstructured purchasing is a silent budget killer. It starts innocently enough—emails, phone calls, casual approvals, “I thought you ordered that,” and prices that drift upward when no one’s watching. But the result is the same every time:

- Missed volume discounts

- Rogue spending

- Lack of traceability

- Confusion between departments

- Suppliers invoicing whatever they “think” was agreed to

A manufacturer’s purchasing process must be controlled and managed just like its production process. Otherwise, costs will creep upwards and out run savings.

The Fix: Standardized Procurement Documentation

This is where tools like those at GetYourPurchasingDocuments.com become non-negotiable because they organize, control, and manage the company ‘spend.’

Protect your IP by using Unilateral and Bilateral NDAs.

- NDA Templates -> /supplier-confidentiality-agreement-unilateral/

Download the Purchase Requisition template and eliminate rogue spending.

- Purchase Requisition Form -> /purchase-requisition-template/

Evaluate new suppliers quickly and easily with a structured Supplier Self-Assessment Survey.

- Supplier Self-Assessment Survey -> /supplier-self-assessment-survey/

Use the RFQ template to capture total cost inputs, not just unit price.

- Request for Quotation (RFQ) -> /request-for-quotation-rfq-template/

Standardize your purchasing workflow with a Purchase Order Template

- Purchase Order (PO) -> /purchase-order-template/

Ensure contract compliance using PO Terms and Conditions

- PO Terms and Conditions -> /purchase-order-terms-and-conditions/

Require a Goods Receipt Note for consistent communication, three-way-match, and inventory accuracy.

- Goods Receipt Note -> /goods-receipt-note-template/

By using these basic tools, you create a closed-loop procurement system.

Suddenly every transaction becomes:

- Visible

- Traceable

- Appropriately approved

- Managed for cost-control and savings

- Audit-ready

- Protected from “informal interpretation”

Companies adopting standardized procurement tools reliably cut manufacturing costs by 3–5% simply by eliminating chaos and enforcing consistency.

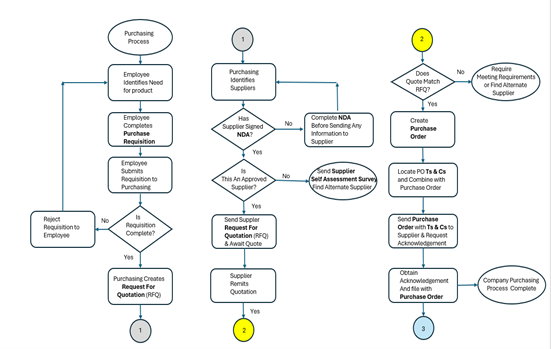

A structured Purchasing process flow can cut manufacturing costs. A flow chart follows this outline.

1. An employee or requestor identifies a need for material or service.

2. The requestor completes a company approved standardized Purchase Requisition (PR).

3. The requestor submits the requisition to Purchasing for review.

a. If the PR is complete, a Buyer is assigned and the Buyer creates a Request for Quotation (RFQ).

b. If the PR is incomplete, it is returned to the employee identifying the reason it was rejected and asked to correct any errors and resubmit the PR.

4. When in possession of a completed PR, the Buyer identifies suppliers that can provide the product or service.

a. If the company has approved suppliers, the Buyer confirms that the supplier has an active and completed non-disclosure agreement (NDA) with the company.

b. If there are not any approved suppliers, or if a previously approved supplier has an inactive NDA, the Buyer works with the supplier to complete an NDA.

5. Once there is a complete NDA on file, the Buyer checks to see if the supplier is an approved supplier.

a. If the supplier is an approved supplier, then the Buyer can send the supplier the RFQ.

b. If the supplier is not an approved supplier, then the Buyer starts the supplier approval process and asks the supplier to complete and return a Supplier Self-Assessment Survey.

Note: This is the beginning of the approval process for a new supplier and supplier approval is an extensive and detailed process outside of this article.

6. Once a supplier has an NDA in place and is an approved supplier, the Buyer sends the RFQ requesting pricing.

7. When the supplier returns a complete quotation, the Buyer reviews the quotation to see if it matches the requirement(s) on the PR and RFQ.

a. If the quotation does not match the RFQ and Purchase Requisition, the quotation is rejected and a response sent to the supplier.

b. If the quotation is completely in line with the RFQ and PR, the Buyer will decide if the pricing, quantities, etc. are acceptable. For this exercise, the quotation is acceptable.

8. The Buyer creates a purchase order (PO).

9. The Buyer combines the PO with the Purchase Order (PO) Terms and Conditions (Ts & Cs) and transmits these documents to the supplier requesting an Acknowledgment of the PO.

Note: For this exercise we will assume that the supplier agrees with the PO and Ts & Cs as written and acknowledges the PO in writing.

10. The Buyer files the PO and acknowledgement.

a. At this point the company purchasing process is complete.

b. The Next step for Purchasing is to monitor the ‘Open Order’ Report and ensure delivery of product(s) or completion of service(s).

11. When the product(s) are delivered, or services performed, the Receiving department verifies the delivery of the product(s) (that the packing list matches the delivered goods or the service(s) performed meet the PR). Once verified, the Receiving department will complete a Good Received Note or Log the Receipt on a Receiving log and in the ERP / MRP system if applicable.

Note: In this example we will assume that the delivery of product or service provided meets the requirements on the purchase order.

12. Receiving then files the packing list(s) should any review be needed.

Step 2: Cut Manufacturing Costs With Supplier Prequalification and Supply Base Consolidation (3–5% Savings + Quality Gains)

As the saying goes:

You can’t manage what you don’t measure.

Most manufacturers work with too many suppliers—often because no one has ever stepped back to ‘analyze’ performance, redundancy, or total ‘spend.’ A bloated supply base inflates:

- Pricing

- Variability

- Risk

- Administrative workload

- Missed opportunities for leverage

The solution begins with an objective evaluation.

Start With a Supplier Self-Assessment Survey

The Supplier Self-Assessment template at GetYourPurchasingDocuments.com forces suppliers to disclose:

- Operational capabilities

- Certifications

- Quality systems

- Financial stability

- Capacity constraints

- Sub-supplier dependencies

- Environmental and compliance programs

This reveals which suppliers are truly world-class—and which are liabilities waiting to explode. The use of a Self-Assessment Survey can cut manufacturing costs by screening and eliminting those ‘potential sources of supply’ that cannot meet your company’s need for performance in delivery, quality, and cost saving deployment of invaluable resources.

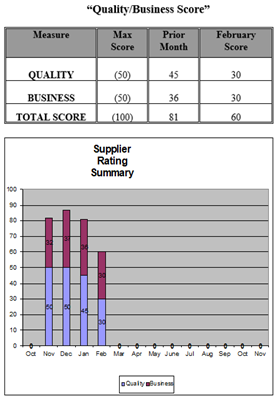

Through https://mscsgrp.com , learn how companies can run structured supplier performance programs that evaluate:

- Cost

- Delivery

- Quality

- Responsiveness

- Continuous improvement maturity

Once scored, the smart play is consolidation.

Fewer suppliers =

- Higher volumes per supplier

- Better price leverage

- More consistent quality

- Reduced Administrative effort

- Stronger partnerships

Well-executed supplier consolidation reliably generates 3–5% savings and can dramatically improve reliability without touching engineering design.

Suggested Image: A bar chart comparing supplier performance on quality, delivery, cost.

Alt text: Supplier performance evaluation to improve cost and quality.

Step 3: Focus on Total Cost of Ownership (TCO) When You Cut Manufacturing Costs Not Unit Price (5–8% Savings)

Chasing the lowest piece price is a rookie move. It’s the procurement equivalent of buying the cheapest car on the lot and then acting surprised when the repair bills show up carrying baseball bats.

Unit price is only one slice of the real cost picture.

The Real Cost Drivers Include:

- Freight and fuel surcharges

- Packaging requirements

- Lead time and inventory carrying cost

- Payment terms

- Minimum order quantities

- Rework and scrap

- Supplier reliability

- Engineering or change-order fees

When companies rely on informal RFQs—emails, spreadsheets, phone calls—these drivers remain invisible. Suppliers typically quote apples, oranges, and pineapples, and procurement teams pretend they’re all the same.

The Fix: Cut Manufacturing Costs by Using a Formalized RFQ Template, Process, and Summary

This creates transparency, eliminates hidden costs, and often uncovers:

- Freight inefficiencies

- Overly restrictive payment terms

- Excessive minimum order quantities

- Supplier-driven pricing games

- Opportunities for consignment or VMI

Manufacturers focusing on TCO—not sticker price—and cut manufacturing costs for an additional 5–8% savings across categories.

Download the Purchase Requisition (PR), the Request for Quotation (RFQ), the Purchase Order (PO) Template, and Purchase Order Terms and Conditions (PO Ts & Cs) to control pricing, terms, and supplier performance.

- /purchase-requisition-template/

- /request-for-quotation-rfq-template/

- /purchase-order-template/

- /purchase-order-terms-and-conditions/

Step 4: Contract Smart — Cut Manufactuing Costs by Protecting Your IP, Your Margins, and Your Reputation

A handshake doesn’t hold up in court, and “they promised us” never survives a dispute.

Manufacturers without formal supplier agreements risk:

- Losing intellectual property

- Being stuck with poor performance

- Misaligned expectations

- Cost increases without recourse

- Supply interruptions with no penalty

- Disputes over tooling, ownership, or payment terms

The solution is simple and essential.

Manufacturing supplier contract ensuring IP protection and quality compliance.

Use Clear, Legal Frameworks for Every Supplier Relationship

Documents at GetYourPurchasingDocuments.com such as:

- Non-Disclosure Agreements (NDAs)

- Bilateral and Unilateral Confidentiality Agreements

- Supplier Agreement Templates

- PO Terms & Conditions

…create the legal foundation that protects:

- Engineering drawings

- Proprietary processes

- Tooling ownership

- Pricing structures

- Delivery commitments

- Confidential information

- Quality standards

Meanwhile, MSCSgrp.com integrates these agreements into strategic sourcing frameworks that link:

- Operational goals

- Pricing models

- Capacity planning

- Supplier metrics

- Financial and compliance objectives

Contracts aren’t paperwork. They are risk insurance.

Step 5: Cut Manufacturing Costs by Measuring, Reviewing, and Improving Supplier Performance (The Hidden Engine Behind Sustainable Savings)

Once suppliers are selected, the real work begins.

Performance drifts unless it’s measured, reviewed, and tied to consequences.

Manufacturers who “set it and forget it” experience:

- Rising defect rates

- Missed delivery dates

- Quiet price creep

- Deteriorating responsiveness

- Zero continuous improvement

Supplier Scorecards Create High-Performance Partnerships and Cut Manufacturing Costs by reducing or eliminating performance issues.

Scorecards track:

- Quality PPM

- On-time delivery

- Cost competitiveness

- Responsiveness and communication

- Corrective-action timeliness

- Innovation and value-engineering participation

Companies that conduct quarterly business reviews with suppliers create a culture of transparency:

- High performers rise.

- Low performers improve—or exit.

- New opportunities for savings surface naturally.

MSCSgrp.com helps manufacturers implement KPI dashboards that tie procurement performance directly to:

- Production planning

- Inventory management

- Finance and cash-flow goals

- Supplier Performance

Strong measurements don’t just protect cost, they amplify quality.

Supplier scorecard driving continuous cost reduction and quality improvement.

The Bottom Line: Cut Manufacturing Costs by Enforcing Courses of Action That Pay — Always

Manufacturers who embrace structured procurement gain three advantages simultaneously:

- Reduced cost (10–15% easily achievable)

- Reduced risk (legal, operational, financial, and supply chain)

- Improved quality and delivery consistency

This happens because the organization shifts from reactionary purchasing to systematic procurement excellence.

The Processes Work Because It:

- Removes variability

- Controls decisions

- Increases visibility

- Strengthens supplier health

- Eliminates hidden cost drivers

- Protects the company with contracts

- Holds suppliers accountable with metrics

- Creates alignment between procurement, operations, and finance

Cost savings become predictable.

Quality becomes consistent.

Operations run smoother.

Leadership sleeps better.

Manufacturing plant operating efficiently after procurement process improvements

Start improving your purchasing process today:

• Explore Procurement Templates → https://GetYourPurchasingDocuments.com/

• Learn About Supplier Optimization Consulting → https://mscsgrp.com

Learn more about how to Cut Manufacturing Costs by visiting the link below.

https://www.kornferry.com/insights/featured-topics/workforce-management/how-to-cut-manufacturing-costs-without-cutting-your-workforce