Revolutionize Your Purchasing and Supply Chain Management Practices Today!

- Explore our Documents and Forms and Get What You Need to Take Your Organization to the Next Level Today!

$399.95

Supplier Operations Audit: Why Planning, Procurement, and Logistics Matter

A Supplier Operations Audit is one of the most effective risk-reduction tools a company can deploy before awarding spend to a new supplier. While price, quality certifications, and references matter, they rarely tell the full story. The real risks live inside a supplier’s planning discipline, procurement controls, and logistics execution. A structured audit brings those risks into the light—before they disrupt production, inventory, or customer commitments.

Companies that skip this step are often surprised later by missed lead times, material shortages, poor schedule adherence, or weak internal controls. A Supplier Operations Audit replaces assumptions with ‘firsthand’ evidence and provides decision-makers with a clear view of a supplier’s operational readiness.

What Is a Supplier Operations Audit?

A Supplier Operations Audit is a structured evaluation of how a potential supplier plans production, buys materials, and serves customers. It goes beyond financial stability or ISO certificates and focuses on whether the supplier can consistently fulfil your business requirements.

This type of audit is commonly used during supplier onboarding, strategic sourcing events, or when qualifying a critical or sole-source supplier. It also complements broader supplier risk assessment efforts by identifying operational weaknesses that may not appear in traditional risk scoring models.

A valuable tool, and precursor to an on-site Supplier Operations Audit, can be a request to a potential supplier for a completed Supplier Self-Assessment Survey. The information obtained helps you pre-screen suppliers so that valuable resources needed for on-site visits are used wisely. You can see and download an example using this link.

https://getyourpurchasingdocuments.com/product/supplier-self-assessment-survey/

In addition, if your company hasn’t already done so, you may need to complete a Non-Disclosure Agreement (NDA) with your prospective source prior to getting a Supplier Self-Assessment Survey. You can download an example of this document using the following link.

https://getyourpurchasingdocuments.com/product/non-disclosure-agreement/

Supplier Operations Audit of Planning Capabilities

Planning is where most supplier failures quietly begin. An audit of planning capabilities evaluates how a supplier forecasts demand, schedules production, manages sales orders, and controls production. Weak planning processes often result in expediting, missed deliveries, and excess inventory—costs that are eventually absorbed by the customer.

Key focus areas include demand visibility, sales orders and contracts, production scheduling logic, capacity constraints, and how changes are managed. A supplier with disciplined planning processes demonstrates control, transparency, and the ability to respond to volatility. These findings should directly support and update your supplier risk assessment and ongoing risk mitigation plans.

Supplier Operations Audit of Procurement Controls

Procurement inside a supplier’s organization is a major risk multiplier if left unchecked. A Supplier Operations Audit examines how the supplier controls procurement from sourcing and procuring raw materials to managing sub-tier suppliers with regards to business continuity planning for disruption.

Poor procurement controls can lead to material shortages, quality issues, and uncontrolled cost increases. During the audit, companies should evaluate supplier approval processes and purchase order discipline, lead time management, and how exceptions are handled. These insights align closely with supplier performance scorecard metrics such as on-time delivery, quality performance, and cost stability.

If you would like to see an example of a Supplier Performance Scorecard, please follow the link below.

https://getyourpurchasingdocuments.com/product/supplier-performance-scorecard/

Supplier Operations Audit of Logistics and Delivery Performance

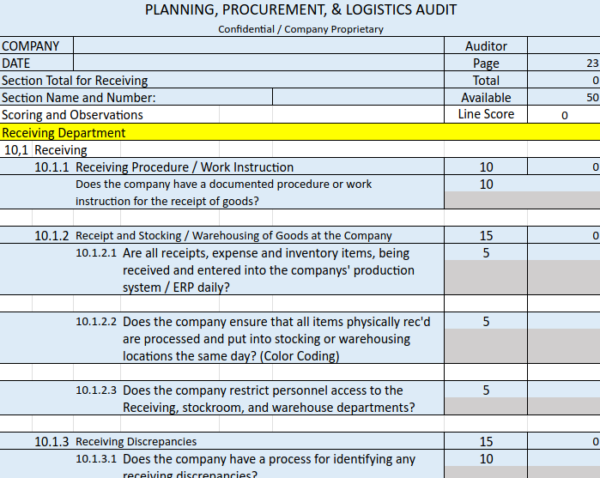

Logistics execution is where operational issues become visible to customers. A Supplier Operations Audit reviews how materials are received, stored, packed, and shipped, along with how delivery performance is measured and corrected.

This includes warehouse organization, inventory accuracy, shipping documentation, and carrier management. Weak logistics processes increase the risk of shortages, damaged goods, and missed customer commitments. Findings from this section should feed directly into logistics-related performance metrics and corrective action tracking within your supplier performance framework.

How a Supplier Operations Audit Reduces Supply Chain Risk

The primary value of a Supplier Operations Audit is risk reduction. By validating planning discipline, procurement controls, and logistics capability upfront companies can avoid onboarding suppliers that lack the maturity required to support their operations.

Audit results also provide objective data that strengthens contract negotiations. Identified gaps can be addressed through corrective action plans, service level agreements, and clearly defined expectations embedded within supplier contracts and terms & conditions. This creates accountability before problems occur, not after.

You can learn more about reducing Procurement Operations Risk by standardizng your company’s procurement processes by reading the article, “Essential Procurement Document Toolkit: Ready-to-Use Templates for Smarter Purchasing and Cost Control” by following this link:

When to Perform a Supplier Operations Audit

A Supplier Operations Audit should be conducted when qualifying a new or critical supplier or when expanding an existing supplier’s scope. It is also valuable when there are repeated performance issues or as part of a broader supplier development initiative.

Organizations that institutionalize this audit process build more resilient supply chains, reduce firefighting, and build ‘trust’ with long-term suppliers that translate into higher levels of supplier performance.

You can find an extensive Supplier Operations Audit – Planning, Procurement and Logistics at GetYourPurchasingDocuments.com by following the link below.

You can also learn more about supplier audits by accessing the link below.

https://www.deltek.com/en/manufacturing/qms/supplier-quality-management/supplier-audit