Revolutionize Your Purchasing and Supply Chain Management Practices Today!

- Explore our Documents and Forms and Get What You Need to Take Your Organization to the Next Level Today!

$79.95

A Pareto Analysis is an effective tool for identifying cost-saving opportunities in both direct and indirect ‘spend.’ By applying the 80/20 rule, companies can focus on the top 20% of categories or suppliers that drive 80% of total spend.

This targeted approach helps prioritize sourcing efforts, renegotiations, and process improvements where they will have the greatest financial impact. For direct spend, it highlights high-cost materials; for indirect spend, it uncovers inefficiencies and standardization opportunities.

The result is a more strategic allocation of resources, enabling procurement teams to reduce costs and improve performance with data-driven decision-making.

$99.95

Customers Demand Flexibility in Delivery – Procurement Delivers Using Purchase Order Change Forms

A purchase order change form exists for one simple reason: purchasing never goes exactly as planned. Specifications evolve, quantities shift, delivery dates move, and pricing changes – often after a purchase order has already been issued. When organizations lack a structured way to manage those changes, procurement turns into damage control. Forgotten scope changes, missed approvals, and downstream cost impacts quietly erode margins and create disputes that no one budgeted for.

This is where disciplined documentation separates professional procurement teams from expensive improvisation.

Why A Purchase Order Change Form Can Create Risk Without Control

In the real world, most PO changes start informally. A phone call with a supplier. A “quick email” confirming a revised delivery date. A verbal agreement to add services. These shortcuts feel efficient in the moment, but they create serious exposure across the purchase order lifecycle.

Without Purchase Order Change Control, teams lose visibility into what was approved, when it changed, and who authorized the change. Finance receives invoices that don’t match the original PO. Operations receive partial or incorrect deliveries. Suppliers claim approval that no one can prove or disprove. The result is rework, delays, and uncomfortable conversations during audits.

A standardized change order form in procurement brings those loose ends back under control.

The Role of a Purchase Order Change Form in Procurement

A purchase order change form is the formal mechanism used to document, approve, and communicate any modification to an existing purchase order. This includes price adjustments, quantity changes, scope expansions, delivery updates, or contract alignment issues. In practice, it functions as a procurement change management form that protects all parties involved.

Used correctly, it ensures every Purchase Order modification follows a documented path rather than relying on tribal knowledge or inbox archaeology.

On GetYourPurchasingDocuments.com, this process aligns naturally with other standardized procurement forms such as the Purchase Requisition, Approval Limits, and Purchase Order templates—creating continuity instead of fragmentation.

You can find examples of a Purchase Requisition Form, Approval Limits, and a Purchase Order form using the links below.

3 STEPS TO A COMPLETE PURCHASE REQUISITION FORM

REDUCE RISK USING APPROVAL LIMITS IN PURCHASING

A PURCHASE ORDER FORM REDUCES RISK AND COST

Change Order vs Amendment: Why A Purchase Order Change Form Matters

One common point of confusion is a ‘change order’ vs amendment. While both alter an agreement, a change order typically applies to operational or commercial adjustments tied to an active PO, while amendments often relate to broader contract terms. A Purchase order amendment form may address legal language, whereas a PO change form focuses on execution details that impact cost, delivery, or scope.

Understanding that difference helps teams apply the right document at the right moment—without muddying legal and operational boundaries.

How the Change Order Process Works in Procurement

A disciplined change order process procurement follows a predictable sequence:

First, a PO Change request form is initiated when a change is identified. That request captures what is changing, why it’s necessary, and the financial or operational impact.

Next, the request moves through a defined Change Order approval workflow aligned to approval limits and financial authority. This step eliminates guesswork and prevents unauthorized commitments.

Once approved, the change is formally issued using a PO revision document template, ensuring version clarity and consistency. Finally, a supplier notification change order is sent so the supplier is working from the same approved baseline as internal teams.

This closed-loop process creates an audit trail for PO changes that stands up to internal reviews and external audits alike.

Solving the Most Common Procurement Pain Points Using a Purchase Order Change Form

The benefits of PO change forms are not theoretical – they address daily frustrations procurement teams face.

Forgotten scope changes disappear because every adjustment is logged. Missed approvals are eliminated by routing changes through documented workflows. Downstream cost impacts are identified early instead of surfacing as invoice surprises. Finance gains confidence in three-way matching, and operations avoid delivery confusion caused by outdated PO versions.

Just as importantly, version control purchase orders become manageable. Teams know which PO current, what revisions exist, and why each change was made. That clarity alone saves hours of backtracking.

Compliance, Consistency, and Audit Readiness Using Purchase Order Change Forms

From a governance standpoint, a purchase order change form supports ‘procurement documentation compliance’ by enforcing standardized behavior. Auditors don’t want explanations, they want evidence. A documented change order’s process shows that purchasing decisions are deliberate, approved, and traceable.

When combined with standardized procurement forms from GetYourPurchasingDocuments.com, companies create a repeatable system instead of reinventing controls for every exception.

How to Update a Purchase Order the Right Way

For teams wondering how to update a purchase order without creating confusion, the answer is consistency. Do not overwrite the original PO. Do not rely on email chains. Use a formal change document that references the original order, captures the revision, and preserves history.

This approach aligns seamlessly with broader procurement best practices and reduces supplier disputes by keeping everyone aligned on what is current and approved.

Turning Process into Protection By Using a Purchase Order Change Form

At MSCSgrp.com, procurement change management is treated as a risk-reduction strategy, not administrative overhead. A purchase order change form is a simple document, but it solves complex problems—financial missteps, compliance gaps, and supplier misunderstandings.

If your organization already uses structured Purchase Orders, Approval Limits, and Receiving controls, this form is the missing link that keeps everything synchronized.

Download the ready-to-use Purchase Order Change Form from GetYourPurchasingDocuments.com to immediately standardize how your team handles PO revisions, protect margins, and eliminate undocumented changes before they become expensive lessons.

Process beats memory. Documentation beats debate. And ‘controlled change’ beats chaos—every time.

$199.95

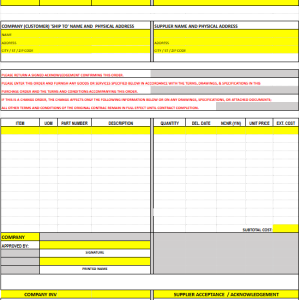

A Purchase Order Form is one of the most critical documents for control that a business can use when contracting for products and services. While it is often viewed as routine paperwork, a properly executed purchasing document is one of those cornerstone tools for financial discipline, operational clarity, and supplier accountability. Companies that fail to use a formal purchase order consistently expose themselves to unnecessary cost, risk, and internal confusion.

At its simplest level, using submitted purchasing requisitions, a purchase order documents what is being purchased, from whom, at what price, and under what terms. Once accepted, it becomes a binding supplier agreement that protects both parties by clearly defining expectations before work begins or goods are shipped. This clarity is essential for companies that want predictable outcomes rather than costly surprises. For more informaiton on Purchasing Requisitions, please visit Purchasing Requisitions System: The Digital ‘EZ Requisition Program’ – Home

The Costs and Risks Increase Without A Formal Purchase Order Form

Organizations that rely on emails, verbal approvals, or loosely written quotes instead of a purchase order often believe they are saving time. They are deferring problems. Without standardized procurement documentation, there is no single, authoritative record of the transaction. This leads to disputes over pricing, scope, delivery, and payment terms—issues that consume far more time and money than proper documentation ever would.

A formal purchase order form eliminates ambiguity. It ensures that suppliers understand exactly what they are expected to deliver and provides internal teams with a clear reference point throughout the transaction lifecycle.

A Purchase Order Form Strengthens Financial and Spend Controls

One of the most important functions of a formal purchase order is enforcing purchasing controls. By requiring approvals before a commitment is issued, the organization ensures that spending aligns with policy, budget, and authority limits. This discipline prevents unauthorized purchases and protects the company from accidental or inappropriate commitments.

A structured purchase order form also supports clear spending authorization, ensuring that only designated individuals can approve purchases at defined dollar thresholds. This safeguard is critical not only for audit readiness but also for maintaining trust between procurement, finance, and leadership teams.

Supporting the End-to-End Procurement Process Using a Purchase Order Form

A purchase order anchors the entire procurement process. Procurement teams use it to formalize sourcing decisions, operations teams rely on it to plan and receive deliveries, and accounting uses it to validate invoices. Without this shared reference, departments operate in silos, increasing the risk of errors and delays.

When paired with receiving documentation, these purchasing documents enable a clean three-way match between the purchase order, goods receipt, and supplier invoice. This process is one of the most effective ways to prevent overbilling, duplicate payments, and invoice disputes. You can learn more about a Goods Receipt Note here GOODS RECEIVED NOTE AND RECEIVING LOG PROCESS and a Sales Invoice here Sales Invoice with Work Instructions

Improving Supplier Performance and Accountability with A Purchase Order form

Clear expectations drive better supplier behavior. A procurement template communicates requirements in writing, reducing misunderstandings and setting measurable standards for delivery, pricing, and quality. When issues arise, the purchase order form provides objective documentation to resolve them quickly and professionally.

Suppliers also benefit from this clarity. A standardized purchase order template removes guesswork and ensures that suppliers receive consistent, complete information with every order. This consistency improves turnaround time and strengthens long-term relationships.

A Purchase Order Form Depicts Audit Readiness and Risk Reduction

From an audit and compliance perspective, the purchase order is indispensable. It creates a permanent record of why a purchase was made, who approved it, and under what terms. This documentation protects the company during audits, internal reviews, or disputes by demonstrating that purchasing decisions follow established controls.

Companies that consistently use these formal purchasing documents are better positioned to identify spending trends, enforce policy compliance, and reduce financial missteps across the organization.

Why Use the Purchase Order Form from GetYourPurchasingDocuments.com

The purchase order form available on GetYourPurchasingDocuments.com is built around real-world procurement best practices, not a generic boilerplate. It captures all critical commercial, operational, and financial details required to support controlled purchasing while remaining practical for daily use.

This ready-to-use document helps organizations immediately improve structure, accuracy, and accountability without lengthy design or customization efforts. It is suitable for manufacturers, service providers, and growing businesses that want professional grade purchasing discipline.

The Bottom Line

A purchase order form is not optional paperwork—it is a control mechanism that protects cash flow, enforces accountability, and aligns internal teams with suppliers. Organizations that implement a standardized purchase order form reduce risk, improve efficiency, and gain visibility into their spending. Those that do not eventually pay for the lack of structure through errors, disputes, and lost margin.

In procurement, discipline always costs less than disorder—and the purchase order form is where that discipline begins.

If you do not have a purchase order form and need an illustration of one, you can download a copy using the link below. This Excel form comes with three Tabs on the form, i.e., a Tab with a blank form, a Tab Identifying each field on the form and a Tab defining the information to be entered in each field.

$399.95

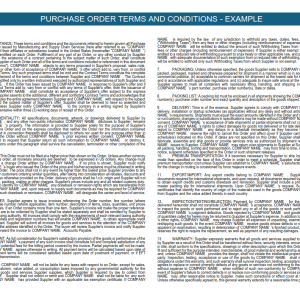

Set the Standard with Suppliers Using Purchase Order Terms and Conditions

When it comes to procurement, consistency comes in the form of ‘control.’ Every company is different so the Purchase Order Terms & Conditions Form from Get Your Purchasing Documents provides a great starting point to build a legal backbone every manufacturing and supply-chain team needs to protect their company from supplier disputes, missed deliveries, and hidden liabilities.

This editable starter form helps you develop protection so that your purchase orders become enforceable contracts, not just order confirmations. Each clause is crafted from the standpoint to reflect industry best practices in manufacturing procurement, giving you clarity, compliance, and confidence in your transactions.

Why Every Company Needs This Form

Procurement isn’t just about placing orders; it’s about managing risk. Without standardized terms and conditions, your business may face:

- Conflicting supplier terms that override your policies

- Unclear definitions of delivery, inspection, or payment expectations

- Costly disputes over defective or delayed goods

- Legal exposure in global supply-chain operations

Our Purchase Order Terms & Conditions Form puts you on the path of eliminating that uncertainty by codifying your expectations—so every vendor, regardless of region or contract size, operates under the same enforceable framework.

—

Key Features and Benefits

✅ Adapt, Review, Ready to Use

The form is provided in an editable format so that you can adapt the terms and conditions to your needs. You don’t have to start from scratch, but you should request a legal review. You can download and enter your company and supplier information to get started.

✅ Built for Manufacturing Procurement

The clauses reflect the realities of industrial purchasing—from raw materials to contract manufacturing—with clear definitions for goods, services, and deliverables.

✅ Reduces Risk and Disputes

Protect your company from non-conforming goods, late deliveries, and warranty issues. Clauses include coverage for inspection rights, governing law, liability, and risk of loss.

✅ Creates Consistency Across All Spend

Standardized language keeps every buyer and every PO aligned. Whether you’re issuing $5,000 or $5 million in spend, the rules stay consistent.

✅ Supplier Clarity = Fewer Delays

Suppliers understand exactly what’s expected, reducing misinterpretations and negotiation friction.

✅ Integrates with Your Procurement Tools

Add this form to your ERP system, procurement workflow, or supplier onboarding package for smooth automation and compliance tracking.

What’s Included

Your purchase includes:

- Editable Form – Professionally formatted Word document for easy customization

- Procurement-Driven Clauses – Covering definitions, acceptance, payment, inspection, warranties, and dispute resolution

- Legal Best-Practice Language – Standardized across goods, services, and hybrid procurements

- Version Control Ready – Update and reissue as your corporate policies evolve

Who Should Use This Document

- Procurement Managers and Category Leaders

- Supply-Chain and Operations Directors

- Contract Manufacturing and OEM Partners

- Consultants and Procurement Service Providers

- Finance and Compliance Teams

If you manage suppliers, sign off on purchases, or lead sourcing projects, this document belongs in your toolkit.

How It Helps Your Organization

| Challenge | Solution with Our Form |

| Suppliers send back conflicting terms | Your PO T&C can override all alternate conditions |

| Vague delivery expectations | Clear definitions of delivery, acceptance, and rejection rights |

| Disputes on non-conforming goods | Explicit inspection, warranty, and return clauses |

| Global supplier risk | Standardized governing-law and liability language |

| Manual legal review delays | Pre-approved template ready for consistent use |

Perfect for Global and Domestic Procurement

Whether sourcing components globally from Malaysia or buying raw materials locally, this form helps to ensure you’re contractually protected.

Pair it with several other forms, i.e., a Non-Disclosure Agreement, Purchase Requisition Form, RFQ Template, and Supplier Self-Assessment Survey, from Get Your Purchasing Documents and work to complete your end-to-end procurement process.

Download and Deploy Today

The Purchase Order Terms & Conditions Form gives your company a professional, legally robust foundation for every purchase order. Safeguard your operations, standardize your processes, and maintain control across your supplier base.

Get started today—download your ready-to-use PO Terms & Conditions Form and protect your company’s bottom line before your next purchase order is issued.

$49.95

Purchase Price Variance (PPV): Why Your Procurement Team Should Track It Relentlessly

Purchase Price Variance (PPV) is one of the most important financial and operational signals inside a disciplined procurement organization. At its core, PPV measures the difference between what a company expected to pay for a material or service and what it actually paid. That delta—positive or negative—reveals how well procurement is controlling cost, executing sourcing strategies, and enforcing purchasing discipline.

In mature organizations, PPV is not treated as a theoretical accounting metric. It is a practical control mechanism used daily to expose pricing drift, supplier behavior, internal compliance gaps, and forecast errors that quietly erode margin.

Purchase Price Variance (PPV) in Procurement Operations

PPV in procurement exists at the intersection of sourcing, finance, and operations. While finance may report the number, procurement owns the behavior that creates it. Every sourcing decision, contract term, price increase approval, or spot buy feeds directly into procurement purchase price variance results.

A strong procurement purchase price variance process depends on standardized documentation. Approved suppliers, controlled purchase orders, and locked pricing terms ensure that actual costs align with negotiated expectations. When companies bypass these controls – buying outside contract, skipping approvals, or allowing uncontrolled changes – PPV becomes volatile and unpredictable.

Spend discipline is supported by using a complete Purchase Order Form and Approval limits in Purchasing. Below are links to examples of these forms.

https://getyourpurchasingdocuments.com/product/purchase-order-form/

https://getyourpurchasingdocuments.com/product/approval-limits-template/

Purchase Price Variance (PPV) Calculation and Standard Cost vs Actual Cost

At a basic level, PPV calculation compares standard cost vs actual cost. The standard cost is typically derived from contracts, price lists, or standard cost rolls maintained in the ERP. The actual cost is what appears on the supplier invoice and is matched during receiving and invoicing.

When actual prices exceed standard cost, PPV turns unfavorable. When procurement secures pricing below standard, PPV is favorable. While the math is simple, the causes are not.

Common drivers include:

• Supplier price increases not formally approved

• Poor contract enforcement

• Incorrect standard cost maintenance

• Emergency or spot purchases

• Volume fluctuations affecting price tiers

This is where purchase price variance accounting becomes critical. Without accurate master data, PPV tells a distorted story – sometimes blaming procurement for accounting errors or outdated standards.

Other important operational pieces to this plan to reinforce accurate cost capture include the Goods Received Note / Receiving Log process and the Three-Way Match when paying invoices. You can find an example of the Goods Received Note / Receiving Log below.

https://getyourpurchasingdocuments.com/product/goods-received-note/

Purchase Price Variance (PPV) Analysis as a Cost Control Tool

Purchase price variance analysis is where PPV shifts from reporting to action. High-performing procurement teams don’t just report PPV—they dissect it. They segment variance by supplier, commodity, buyer, plant, and ‘time period’ to identify patterns that demand correction.

This analysis often reveals deeper cost variance procurement issues such as:

• Non-compliant buying behavior

• Weak supplier negotiations

• Inconsistent volume commitments

• Poor demand planning

For manufacturers, material price variance frequently dominates PPV results. Even small per-unit deviations on high-volume materials compound into a six- or seven-figure exposure over time.

Internal link prompt: Reference your Supplier Performance Evaluation Scorecard to connect PPV trends with supplier accountability.

Purchase Price Variance (PPV) Reporting and Executive Visibility

Effective PPV reporting is concise, consistent, and tied to accountability. Executives do not want spreadsheets full of unexplained numbers. They want to know why PPV moved, who owns it, and what is being done.

Well-designed PPV reports typically include:

• Monthly and YTD PPV trends

• Breakdown by supplier and category

• Favorable vs unfavorable drivers

• Linkage to sourcing actions

When procurement owns the narrative, PPV becomes a credibility builder rather than a defensive exercise. It demonstrates that procurement is actively managing cost, not passively processing orders.

Internal link prompt: Cross-link to Procure-to-Pay Process documentation on MSCSgrp.com to show where PPV fits operationally.

Why Purchase Price Variance (PPV) Is a Procurement Discipline Indicator

Ultimately, Purchase Price Variance (PPV) is not just a financial metric—it is a reflection of procurement maturity. Organizations with clean PPV data typically have strong purchasing controls, standardized processes, and supplier governance. Organizations with erratic PPV often suffer from uncontrolled buying, weak approvals, and undocumented price changes.

When supported by standardized procurement forms, enforced approval workflows, and disciplined supplier management, PPV becomes a powerful lever for protecting margin and improving forecast accuracy.

Protecting company margins begins with using standardized forms such as a Purchase Requisition Form, Request for Quotation template, and a Purchase Order Form to reinforce systemized control. You can find examples of these forms by following the links below.

https://getyourpurchasingdocuments.com/product/complete-purchase-requisition-form/

https://getyourpurchasingdocuments.com/product/request-for-quotation-rfq/

https://getyourpurchasingdocuments.com/product/purchase-order-form/

$199.95

Why Every Business Needs a Purchase Requisition Form to Eliminate Errors and Streamline Procurement

Purchasing should not feel like a scavenger hunt. Yet in many organizations without a complete Purchase Requisition Form, especially fast-moving manufacturing environments, buyers and approvers are constantly piecing together incomplete requests, chasing down missing details, and interpreting vague emails like they’re reading ancient tablets. This chaos drains time, increases risk, and raises the odds of costly mistakes.

A properly structured Purchase Requisition form (PR), like the ready-to-use version on GetYourPurchasingDocuments.com, https://getyourpurchasingdocuments.com/product/purchase-requisition-form/ restores order by standardizing what information the organization must gather before a purchase moves forward. It’s the single simplest step a company can take to tighten controls, speed up approvals, and dramatically reduce purchasing errors.

A Complete Purchase Requisition form Eliminates Guesswork and Reduces Costly Mistakes

Errors in procurement almost always come from missing or unclear information—wrong part numbers, incorrect quantities, incorrect supplier assumptions, outdated pricing, or missing technical requirements. A complete Purchase Requisition template (forces clarity upfront by requiring all relevant data in one place:

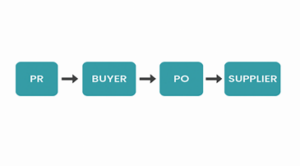

Procurement Workflow

- Item descriptions

- Part numbers and revisions

- Quantities, units of measure, and delivery requirements

- Supplier recommendations

- Required attachments (quotes, drawings, SOWs, certifications)

- Account numbers and cost centers

- Requester information and approval routing

When these details are collected at the beginning by using standardized purchasing forms, buyers can execute quickly and accurately. When they’re missing, procurement becomes a detective agency. A standardized PR removes ambiguity and prevents the silent killers of productivity—rework, delays, and unnecessary back-and-forth.

A Purchase Requisition form Creates a Streamlined Procurement Workflow Speeding Up the Purchasing Process

There’s a myth that adding structure slows things down. A good PR speeds everything up because it eliminates the “stop-and-start” delays that happen when buyers are forced to chase missing data. With a complete requisition:

- Approvers know exactly what they’re signing off on.

- Buyers can convert the PR into an RFQ or Purchase Order without rewriting information.

- Finance gains accurate documentation for accruals, budgeting, and audits.

- Suppliers receive clean, unambiguous orders—reducing questions and shipment errors.

The PR acts like an upstream Procurement Documents filter ensuring every downstream step moves smoothly. When implemented correctly, users spend less time on the process because they’re not circle-backing to fix preventable mistakes.

A Purchase Requisiton Forms Create Traceability, Accountability, and Policy Compliance

In any company with spend visibility goals, compliance requirements, or audit expectations, a Purchase Requisition is not optional—it’s the backbone. It creates a documented record of who requested what, who approved it, and why the expenditure was necessary.

This protects your organization from:

- Unauthorized commitments

- Budget overages

- Rogue spending

- Supplier favoritism

- Audit findings

Purchasing best practices include a well-designed Purchase Requisition Form because it includes clear approval signatures or digital signoffs aligned with an Approval Limits in Purchasing table (https://getyourpurchasingdocuments.com/product/approval-limits-template/) That ensures the ‘spend’ or approval authority is followed, and every purchase traces back to a valid need.

A Purchase Requisition form Teaches Users What “Good” Looks Like

Most employees aren’t procurement experts, and they shouldn’t have to be. Your document solves this by embedding field definitions, instructions, and examples directly into the template. This reduces training time and helps new buyers, engineers, and office staff submit clean requisitions from day one.

It’s not just a form—it’s a process guide that makes the whole company better at purchasing.

Why A Purchase Requisition Form Matters

Many companies think they have a “PR process” because they use emails or spreadsheets. That’s not a process—that’s improvisation.

Your ready-made Purchase Requisition provides:

- A consistent structure

- A repeatable workflow

- Full transparency

- Faster cycle times

- Fewer errors

- Stronger internal controls

It takes the guesswork out of purchasing and replaces it with discipline, clarity, and accuracy—the foundation of world-class procurement. Download a copy of the Purchasing Requisition today https://getyourpurchasingdocuments.com/product/purchase-requisition-form/.

Learn more about Purchase Requsitions and the Procurement Process by visiting Manufacturing and Supply Chain Services at

Purchasing Requisitions System: The Digital ‘EZ Requisition Program’ – Home

$99.95

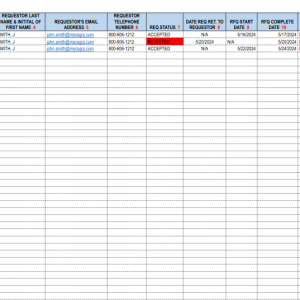

A PURCHASE REQUISITION LOG: KEY TO ORGANIZING AND CONTROLLING PURCHASING REQUESTS

A purchase requisition log is one of the most overlooked yet powerful control tools in a company’s procurement environment. While many organizations rely on individual purchase requisition forms to initiate requests, the log is what transforms those individual documents into a system of records. It provides visibility, accountability, and governance over how internal requests are created, reviewed, approved, and ultimately converted into financial commitments.

How a Purchase Requisition Log Works

Organization

At its most basic level, a purchase requisition log is a centralized register that records every purchase request submitted within the organization. Each entry typically references the originating Purchase Requisition Form, the requester, department, estimated value, approval status, and downstream actions. This structure ensures that requests are not treated as isolated events but as part of a controlled and traceable procurement process.

Control

One of the primary benefits of maintaining a purchase requisition log is effective ‘spend control.’ Without a log, requisitions can be approved in silos, creating blind spots where multiple departments unknowingly request similar items or exceed budget thresholds over time. A centralized log allows procurement and finance teams to monitor aggregate demand and intervene before spending drifts outside acceptable boundaries. This visibility reinforces consistent purchasing controls across departments and locations.

You can learn more about the financial benefits uncovered when controlling the Maintenance, Repair, and Operations costs by following the link below:

MRO Items: Organization, Control & Spend Optimization – Home

Tracking

The log also plays a critical role in purchase requisition tracking. From initial submission through approval and fulfillment, each request can be monitored for status, delays, or escalation needs. This tracking capability helps organizations identify bottlenecks in the approval workflow, such as recurring delays at certain authorization levels or incomplete submissions that stall progress. Over time, these insights allow companies to refine approval structures and improve cycle times without sacrificing control.

A Purchase Requisition Log Assists With Control of Spend

From a governance perspective, the purchase requisition log strengthens internal ‘spend’ authorization by aligning requests with the established approval limits for company personnel. When approval thresholds are enforced and documented in the log, management gains confidence that spending authority is being exercised appropriately. This reduces the likelihood of informal commitments or retroactive approvals that often lead to disputes and unauthorized spending.

You can learn more about the Authorization to Commit Funds or an Approval Limits in Purchasing table by following this link:

https://getyourpurchasingdocuments.com/product/approval-limits-template/

A Purchase Requisition Log Supports Audits and Review

A well-maintained log also serves as a defensible audit trail. Auditors frequently ask not only whether purchases were approved, but whether approvals occurred before commitments were made. The purchase requisition log provides time-stamped evidence that requests were reviewed, authorized, and documented in accordance with policy. This directly supports stronger financial controls and reinforces the organization’s broader internal controls framework.

Control and Steps – Procure-to-Pay Process

Within the broader procure-to-pay process, the purchase requisition log functions as the bridge between demand identification and transactional execution. Approved requisitions in the log can be matched to purchase orders, receipts, and invoices, ensuring alignment across procurement, receiving, and accounting. This traceability reduces reconciliation issues and supports three-way matching disciplines that protect against overbilling and processing errors.

Another important function of the purchase requisition log is its role in standardizing procurement documentation. When requisitions are logged consistently, organizations create a reliable dataset that can be analyzed over time. Procurement teams can review historical requests to identify recurring needs, justify strategic sourcing initiatives, or challenge unnecessary demand. Finance teams can use the same data to support budgeting, forecasting, and variance analysis.

For organizations still relying on email approvals or disconnected spreadsheets, the absence of a purchase requisition log often results in fragmented decision-making. Requests are approved without context, spending patterns go unnoticed, and accountability becomes difficult to enforce. In contrast, companies that implement a formal log gain a single source of truth that supports compliance without slowing down the business.

You can learn more about the Procure-to-Pay Process by following this link:

Add Link to the Blog “The Complete Procure-to-Pay-Process: A Step by Step Guide for Businesses

The Bottom Line – The Purchase Requisition Log Provides Organization and Control

Using a professionally designed purchase requisition log—such as those available on GetYourPurchasingDocuments.com—helps organizations implement this control quickly and correctly. These tools are designed to integrate with related documents, including the Purchase Requisition Form, approval limits tables, and purchase order templates, creating a structured and auditable workflow from request to payment. When paired with other resources on GetYourPurchasingDocuments.com, the log becomes part of a cohesive control environment rather than a standalone spreadsheet.

Ultimately, the purchase requisition log is not administrative overhead. It is a control mechanism that protects company assets, enforces policy, and improves decision-making. By providing visibility into what is being requested, who is approving it, and why, the log ensures that the procurement process remains disciplined, transparent, and aligned with organizational objectives.

In mature procurement organizations, the purchase requisition log is treated as a strategic control point. It enables better planning, reduces risk, and ensures that spending decisions are intentional rather than reactive. When implemented correctly, it becomes a quiet but powerful guardian of financial integrity.

Download a copy today and begin protecting your company’s profits.

$99.95

A Purchasing Record—often referred to operationally as a Buy Card—is one of the most overlooked tools in a disciplined procurement environment. When designed correctly, it gives organizations a controlled, auditable method for handling low-dollar purchases without weakening approval discipline, spend authorization, or internal controls.

For start-ups and small businesses, the Purchasing Record often begins as a manual solution. That’s not a flaw; it’s a bridge. Until a full procure-to-pay system or ERP is implemented, this document forms the backbone of purchasing documentation and establishes early financial controls that scale later.

The risk shows up when small purchases are treated as harmless. Employees bypass formal requests [i.e., Purchase Requisitions (PR)], invoices arrive without context, and accounting is left reconstructing who approved what—if anyone did. The Purchasing Record exists to close that gap and restore traceability before bad habits harden into policy violations.

You can see an example of a Purchase Requisition form by clicking on the link below.

https://getyourpurchasingdocuments.com/product/complete-purchase-requisition-form/

What Is a Purchasing Record and How a Buy Card Works

A Purchasing Record is a standardized document used to authorize and document purchases below a defined spend threshold where issuing a full purchase order would be inefficient. Internally, many organizations call this process a Buy Card, but clarity matters: a Buy Card is not a corporate credit card and not a workaround to procurement policy.

Instead, it is a structured spend authorization record that captures the minimum data required to support audit readiness and downstream reconciliation, including:

- Requestor and department

- Business justification

- Approved spending limits

- Authorized approver

- Supplier details

- Proof of receipt

This creates a defensible procurement audit trail while still allowing speed for operational needs. You can see an example of Approval Limits in Purchasing by visiting the link below.

https://getyourpurchasingdocuments.com/product/approval-limits-template/

Why Purchasing Records Strengthen Procurement Controls

Low-value purchases are where procurement controls quietly erode. Individually, these transactions seem insignificant. Collectively, they create exposure through unauthorized spending, budget leakage, and reconciliation delays.

A Purchasing Record enforces discipline by ensuring every transaction—regardless of size—has documented approval, alignment with approval limits, and clear records of authorized purchases. Without this structure, organizations invite non-PO spending to accumulate outside visibility until an invoice forces the issue.

This is where many companies lose control without realizing it.

Purchasing Record Alignment with Internal Controls and Compliance

From an internal control’s perspective, undocumented purchases are a flashing warning light. A Purchasing Record creates a repeatable, consistent process that aligns procurement activity with financial controls and audit expectations.

Auditors are not chasing perfection; they are looking for consistency and traceability. A documented Buy Card process demonstrates:

- Defined approval authority

- Segregation of duties

- Transaction traceability

- Evidence of spending control

This is especially important for organizations subject to SOX requirements, internal audits, or external financial reviews, where informal purchasing is often the first area challenged.

When to Use a Purchasing Record Instead of a Purchase Order

A Purchasing Record is intended for low-dollar, non-recurring, or time-sensitive purchases where issuing a purchase order would add friction without reducing risk. Typical use cases include maintenance items, operational supplies, emergency purchases, or one-time services.

It should never replace purchase requisitions or purchase orders for recurring, contractual, or high-risk spend. Instead, it functions as a controlled exception within the procure-to-pay process.

In some cases, such as ‘emergency purchases,’ company policy may still require after-the-fact purchase order issuance for system completeness. You can find an example of a Purchase Order Form by clicking on the link below.

https://getyourpurchasingdocuments.com/product/purchase-order-form/

How Purchasing Records Prevent Unauthorized and Non-PO Spend

Non-PO spend is not inherently dangerous. Undocumented non-PO spend is.

A Purchasing Record captures transactions that would otherwise surface only when an invoice arrives in accounts payable. By recording these purchases upfront, organizations gain visibility into buying patterns, enforce approval limits, reduce invoice disputes, and improve budget accuracy.

This is how informal spending becomes structured data instead of noise.

Purchasing Record Integration into the Procure-to-Pay Process

When properly implemented, the Purchasing Record is not a loophole—it is a formal step within the procure-to-pay workflow. It complements purchase requisitions for planned spend, purchase orders for sourced material, approval limits tables for governance, and receiving documentation for validation.

This alignment allows procurement to support operations without surrendering control, even when speed is required. You can find an article that discusses the Procure-to-Pay Process (P2P) at length by clicking on the link below.

https://getyourpurchasingdocuments.com/uncategorized/procure-to-pay-process/

Standardizing the Purchasing Record Template for Consistency

Standardization is where the real payoff happens. A uniform Purchasing Record template removes ambiguity, shortens training time, and ensures consistent application of internal purchasing controls across departments and locations.

Organizations that standardize this document experience fewer policy violations, faster approvals, cleaner audits, and better control of spending. The result is a procurement process that balances agility with accountability—and scales without chaos.

$49.95

A ‘Request for a Proposal’ (RFP) is a strategic business tool used to communicate the needs for product(s) or service(s) in an organized and structured fashion to Sellers (Suppliers).

An ‘RFP’ provides suppliers with project scope, deliverables, timelines, and much more.

The bottom line, a robust RFP process helps organize and streamline the procurement process when quoting projects and is very helpful when competing the company’s business among different sources.

If you need an illustration of a Request for Proposal (RFP) outline, you can download a copy using the link below.

$99.95

Why Every Company Should Use a Formal Request for Quotation (RFQ)

Companies waste an absurd amount of time and money chasing quotes that never match, don’t include the right details, or arrive in a form that’s impossible to compare. A formal Request for Quotation (RFQ) solves that problem. When you use a structured RFQ – like the ready-to-use version available on GetYourPurchasingDocuments.com (Link to RFQ template) – you bring discipline, accuracy, and speed to the quotation process. That directly translates into fewer mistakes, tighter cost control, and faster purchasing cycles.

A well-built RFQ is more than a form. It’s a safeguard. It forces clarity, ensures suppliers receive identical requirements, and creates a clean foundation for evaluating pricing, delivery, and commercial terms without chaos creeping into the process. Companies that rely on informal emails or ad-hoc supplier requests spend more time untangling confusion than making smart sourcing decisions.

A formal RFQ form creates a standardized channel for communication with suppliers, and that standardization is where the magic happens.

Reduced Errors by Providing Every Supplier with the Same Complete Requirements

Most pricing mistakes don’t come from “bad suppliers”—they come from incomplete requirements. When each supplier is reacting to slightly different descriptions, terms, or specifications, your quotes become apples-to-oranges. A structured RFQ eliminates that mismatch by giving every supplier the same set of details at the same time.

A sound RFQ document includes:

- Clear descriptions of the product or service

- Required quantities and units of measure

- Delivery requirements

- Technical drawings or supporting documents

- Terms, conditions, and quality expectations

- Instructions on how to submit pricing

A uniform RFQ also provides sourcing accuracy, i.e., once everyone is quoting from the same foundation, the errors vanish. No more suppliers quoting different part revisions. No more missing freight. No more “I didn’t realize you needed “testing” or “certification” surprises. The form acts as a filter that keeps assumptions out and accuracy in.

When your RFQ sets expectations upfront, the Purchasing and Procurement teams stop spending their days clarifying, correcting, and re-requesting quotes. Time saved is cost saved.

A Streamlined and Repeatable Request for Quotation Process

Speed in procurement comes from accuracy and repeatability. A formal Request for Quotation (RFQ) (Link to the RFQ Template) lets your organization run quotation cycles without reinventing the wheel each time. The RFQ gets the information needed from the Purchase Requisition Form (PR) (Link to Purchase Requisition form) Instead of crafting a new request or digging for old email chains, you simply drop the new requirement into the standard form and send them on to your suppliers. The RFQ and PR forms provide a method and workflow that keeps everything clean, organized, and compliant.

Using a standard RFQ also reduces internal confusion. Everyone in the company, from engineering to operations and finance, sees the same structure for every event. Over time, this consistency builds organizational muscle memory. People submit better requirements. Suppliers respond faster. The entire purchasing quotation process becomes smoother, quicker, and less prone to mistakes.

Companies that use a standard RFQ process routinely shave days or even weeks off their sourcing cycles because they’re no longer trapped in back-and-forth clarifications.

Effortless Integration into a Quote Summary Template for Cost Comparison

One of the biggest advantages of a formal RFQ is what happens after the quotes arrive. Because the RFQ forces suppliers to provide identical information, in a required format, all incoming quotes can be dropped into a quote comparison summary without gymnastics.

These two procurement documents, the RFQ form and a quote summary tab, provide the team with immediate clarity on:

- Total landed cost

- Differences in pricing by line item

- Cost drivers such as tooling, freight, or minimum order quantities

- Delivery times and lead-time risk

- Commercial deviations or exceptions

When all quotes align structurally, your quote summary becomes a quote evaluation tool instead of a reconstruction project. Executives love clean comparisons. Buyers love not having to “guess what the supplier meant.” And finance teams love the audit trail.

Your RFQ is the blueprint. The quote summary is the output. The more structured the input, the more intelligent—and defensible—the sourcing decision.

A Better, Faster, More Accurate Way to Source

A formal RFQ is one of the simplest ways to add professionalism, accuracy, and financial control to your purchasing process. If you want your procurement function to run like a production line—organized, consistent, and error-free—then using a structured RFQ is non-negotiable.

The RFQ template at GetYourPurchasingDocuments.com gives suppliers everything they need, eliminates the noise that causes misquotes, and sets up your team for clean comparison and smarter sourcing decisions. Download a copy today at https://GetYourPurchasingDocuments.com .